Super High Density Olive Crops

The Super High Density olive grove is a revolutionary new agronomic model driven by Agromillora for over 30 years in an effort to solve many of the problems that faced by growers in traditional crops. Our system translates into much more profitable and efficient crops for our customers.

Get the latest news on superintensive crops >

SYSTEM FEATURES

–

SHD Olive crops

• SHD plantation with Smarttree®.

• Clonal propagation of dwarf varieties.

• Varieties featuring fast entry into production.

• Planting patterns (3-4 x 1-1.5 m). High planting density (+1,600 plants/ha).

• Orientation: N-S orientation makes it possible to reduce the street width without shading.

• Harvesting with over-the-row machine.

• Fully mechanised pruning.

ADVANTAGES

–

SHD Olive crops

• Higher productivity per unit of area.

• Total mechanisation from the moment of planting, with the aim of reducing costs and labour.

• Early entry into production, with faster amortisation of the investment.

• Less cultivation work and labour, which is increasingly scarce and costly.

• Fully mechanised harvesting: Increase in speed and efficiency using over-the-row machines.

• High quality of the oil obtained, 100% extra virgin

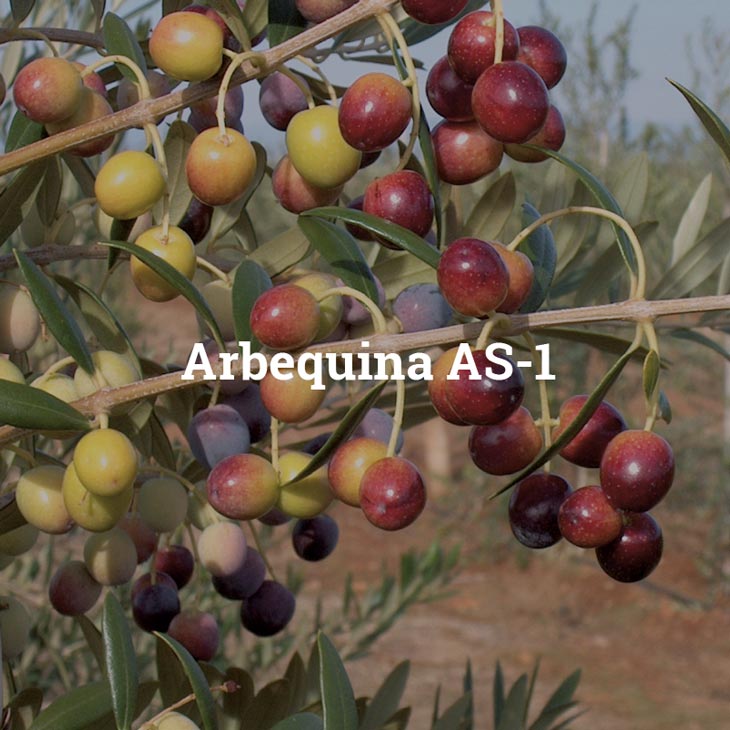

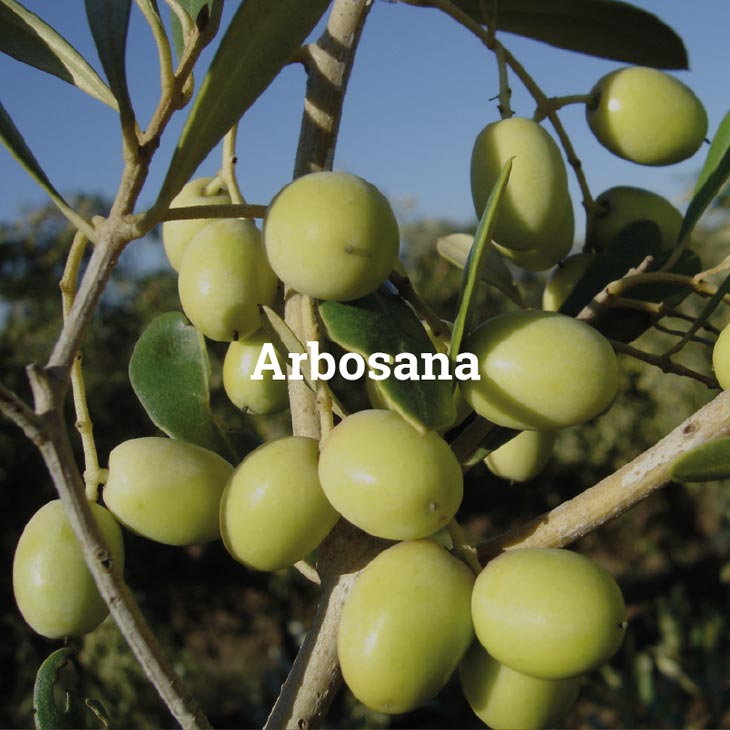

OLIVE TREE VARIETIES COMPATIBLE WITH SHD CULTIVATION

–

SHD Olive crops

Choosing the right variety is one of the core aspects to achieve the objectives of an SHD plantation.

We have six varieties for this system to suit different agro-climatic and crop conditions which likewise meet the stringent demands of the olive sector.

COMPARISON OF VARITIES

–

SHD Olive crops

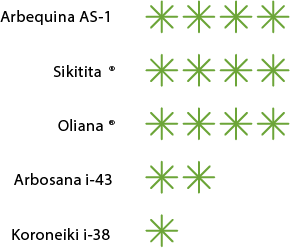

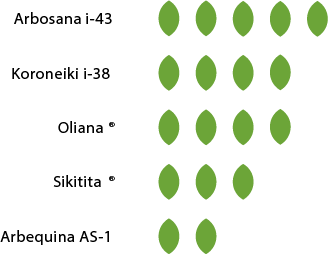

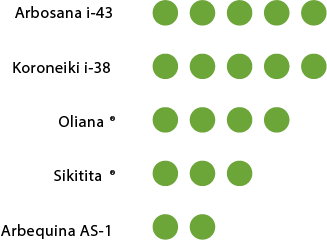

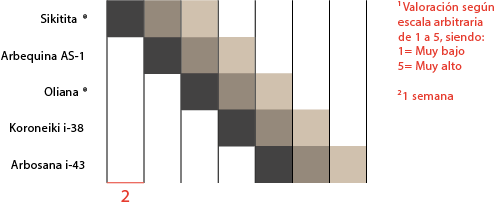

Resistance to cold

Resistance to leaf spot disease

Yield index

Vigour scale

Ripening time

SUPER HIGH DENSITY OLIVE GROVE FEATURES

–

SHD Olive crops

Planting pattern

The most widespread planting patterns currently vary between 3-4 m row distance and 1-1.5 m between trees. This implies planting densities of above 1,600 plants/ha. Choosing a suitable plantation pattern suitable for the agro-climatic features of the area in question and the variety of choice is paramount to the success of the plantation.

Production

Entry into production is very fast. In the third year of planting yield is 3-4 t/ha. The results obtained in these years of experience in different olive-growing areas result in sustained yield values of between 8-12 t/ha. In warm-area plantations, and under appropriate crop management, yields can reach up to 16 t/ha.

Cost effectiveness

The most widespread planting patterns currently vary between 3-4 m row distance and 1-1.5 m between trees. This implies planting densities of above 1,600 plants/ha. Choosing a suitable plantation pattern suitable for the agro-climatic features of the area in question and the variety of choice is paramount to the success of the plantation.

Crop quality

The mechanized harvesting that takes place in the SHD olive grove ensures that fruits can be collected in proper ripening conditions with minimal damage and allows a quick delivery to the mill for grinding. These factors are important when in order obtain extra virgin olive oil (100% extra virgin olive oil) boasting outstanding organoleptic qualities.

Our 30 years of experience working with SHD olive groves have helped us improve how these plantations are managed and implement their cropping system.

The most significant improvement has come with the revolutionary Smarttree plant system, designed for the SHD system.

Smarttree plants are the ideal solution for new super high density plantations, since they allow fully mechanising all growing tasks from planting onwards. This in turn reduces costs, ensures a continuous hedge in the shortest possible time, increases oil production per hectare and improves the efficiency and profitability of a SHD olive grove.

Thanks to this format, planting olive grove plantations can take place in any season, according to the specific climate conditions of the project, avoiding winter in frost-risk zones and the summer in very hot zones.

Know more about Smarttree >

SMARTTREE FEATURES

–

Super High Density Olive crops

• Total mechanisation from the moment of planting, unlike the central axis layout, which implies significant labour savings.

• Maximum genetic and health quality.

• Shorter nursery production time.

• Plant, 60 cm high with numerous branches from 50 cm, with stake.

• Strong root system and developed in inert substrate.

• Plant provided with a plastic protector to protect it from the use of herbicides at the moment of planting and avoiding suckers.

• Ease of transportation and planting.

• Efficiency of the production process

• Mechanized planting. Planting in SHD systems is a highly efficient and highly technical process. Prior to planting, the soil is prepared (with a slope not exceeding 20%), varieties are chosen, and the plantation pattern/orientation of rows designed. Currently, Smarttree plants featuring a plastic protector offer plantation yields that exceed 6,000 plants/day.

• Mechanized pruning. Pruning is certainly one of the key tasks in olive groves and other fruit trees. The SHD system allows mechanising pruning, significantly reducing operating costs. By using our revolutionary Smarttree plant, pruning can be machined completely, thereby considerably boosting crop profitability. The objective of pruning is to keep the olive tree productive, ensuring a correct wood-leaf ratio and keeping it at the right size for the harvesting machine.

• Mechanised harvesting. 100% mechanised harvesting. The same over-the-row machines used for harvesting grapes are employed. This system ensures that 98% of fruits are harvested resulting in minimal damage to both the olive and the tree. Yields may reach 1.5-2 hours/ha and harvesting costs range between 0.03-0.06 €/kg. This type of harvesting allows harvesting olives in a proper state of ripening and rapid delivery of the fruits to the mill for grinding, decreasing potential deterioration and possible undesirable flavours in the oil.

• Hedge formation. The traditional super high density system, featuring the central axis layout, has become a thing of the past, superseded by Agromillora’s new Smarttree free plant formation system. The new system allows full mechanisation of the work related to planting and hedge formation and pruning, resulting in a major cost reduction.

ADVANTAGES OF SMARTTREE LAYOUT

–

Super High Density Olive crops

• Lower initial investment, </ b>since no poles or wires are required.

• Decreased labour necessary during formation, since no tying is involved.

• Earlier entry into production by hectare: Only pinching occurs. Branches are never cut from Smarttree® plants, which exhibit greater development from the very beginning in the nursery.

• Less relevance of attacks and insects that might damage the apical bud.

| First plantations in Andalusia (2000) | Current plantations (2015) | |

|---|---|---|

| Variety | Arbequina | Arbequina, Arbosana, Koroneiki, Sikitita, Oliana |

| Planting patterns | 3*1.35, 4*2, 5*3 | 3.5*1.35 / 3.5*1 |

| Formation system | Central Axis | Smarttree system (free) |

| Support structure | Training (stakes 2,2m +poles +wires) | Stake 70-80 cm |

| Cost of implementation | + | - |

| Pruning | Formation manual for producing olive trees | Fully mechanised (formation and production) |

| Harvest time | 2-2,30 h/Ha | 1,5-2 h/Ha |

| Required staff | + | - |

| Average yield | >12.000 Kg | |

| Duration of planting | ? | >18 |

| Organic SHD olive grove | ? | + |

| SHD non-irrigated olive grove | ? | + |

DEVELOPMENT OF SHD OLIVE GROVE

–

Super High Density Olive crops

NEW CHALLENGES FOR THE SHD OLIVE CROPS

–

Super High Density Olive Crops

At Agromillora we boast over 30 years’ experience in olive growing using SHD systems and we continue spreading our solutions and developments as far as possible so olive sector growers and professionals can take advantage of them. As a result of this experience, we are able to anticipate and understand the new challenges to be overcome in the future by the SHD olive grove.