The increase in the demand for almonds, the development of novel self-fertile and late-flowering varieties, and the establishment of plantations in new irrigated areas have led to significant progress in the productive techniques of almond tree cultivation. One of the most important has been the increase in planting density, due to the development of dwarfing rootstocks. This paper presents a comparison between two training systems with ‘Soleta’ almond cultivar: a super high density (SHD) system using Rootpac-20 dwarfing rootstock versus an open-center training system using GF-677 rootstock. To this end, several parameters related to chlorophyll content (fluorescence and SPAD) and light interception (from photosynthetically active radiation (PAR) measurements) were monitored throughout two vegetative cycles, and other productive conditions (flowering, fruit set and production) were tracked at specific times of the cycle. The open-center system resulted in higher PAR interception than the SHD system, but also in the presence of poorly illuminated fractions of the canopy. Diferences were observed between both systems in terms of average fruit weight and yield per canopy volume. Lower yields were obtained in SHD system than in open-center, which may be significantly increased by adapting the inter-row spacing. However, the degree of eficiency in the use of resources or productive inputs, such as irrigation, was favorable to the new SHD training system, so its potential to become a reference system in modern plantations (using over-the-row harvesters similar to those used for vine and olive trees) seems promising.

The USA, and more specifically California, leads the world production of almonds, with an 80% market share. However, as far as crop area is concerned, the European Union concentrates 39% of the world almond-tree dedicated area, 84% of which is located in Spain, which hence accounts for almost one third of the world area [1]. These over 633,000 ha are mainly concentrated in the Mediterranean area: in Aragon (20%), Catalonia (7%), Valencian Community (17%), Murcia (12%), Andalusia (30%) and Castilla la Mancha (8%) [2].

In just a few years, in Spain the almond industry has gone from being a marginal crop grown in poor and arid soils to represent an alternative production to the traditional ones of deciduous fruit, cereals or citrus. This change in production management has caused the almond tree to currently offer a 20–25% higher profitability than cereals or olive trees for the same farm [3]. At the same time, almond consumption has markedly increased, as world demand has grown at a rate of 5% per year [3].

In Spain, other favorable factors have joined the advantageous international situation, such as the impulse of new late-flowering varieties, barely exposed to spring frosts and self-fertile varieties (less exposed to climatic conditions during flowering), and the introduction of irrigation.

The behavior of very high-density or super-intensive plantations (with over 2000 trees/ha) started to be investigated a decade ago in almond and 25 years ago in olive trees [4,5]. Less vigorous rootstocks, training and pruning systems appropriate to this system and high-effciency over-the-row harvesters (similar to those used for vine or olive trees) have been assessed [6]. This combination of innovations makes it possible to think in a new productive model similar to the one used in deciduous fruit crops,

the two-dimensional (2D), super high density (SHD) or sustainable and effcient system (SES) model [7], based on productive walls and not on individual trees and on the use of dwarfing patterns [7–10].

These patterns make it possible to have smaller and more effcient canopies, and at the same time reduce production costs due to better effciency of water and fertilizers, better accessibility to the canopy and easier mechanization [11]. Hence, although this type of plantation is in an experimental phase and its medium- and long-term behavior is still unknown [6], it may be foreseen that this training system may be able to offer the same advantages, already proven, attained for aforementioned crops (i.e., vine on trellis and SHD olive groves) and for fruit trees [10,12,13]. Some of these advantages include an increase in the effectiveness of phytosanitary treatments and in management, water savings in irrigation, minimization of soil maintenance, early yields, possibility of harvesting with over-the-row machines and robotic harvest of deciduous fruits, reduction of necessary labor and improvement of the profitability of the crop [12,13].

Furthermore, the implantation of these novel training systems can also have a significant impact on light distribution and light interception in the canopy [14–16]. For instance, in certain traditional training systems, the innermost region of the canopy can present problems with “sink leaves” or incorrectly illuminated organs [17], which would be problematic, given that the light environment in a particular area in the tree canopy is known to influence leaf characteristics as well as flowering and fruit production [18,19]. In the almond tree, the regularity of the production requires the formation of a large number of flowers each year (high floral density) and their adequate pollination in order to obtain an acceptable setting and, in turn, a profitable harvest [20–22]. Moreover, in mature almond trees, yields reflect in a large measure the number of fruit and fruit-bearing spurs, and spur survival is reduced by shading of lower or interior branches, an indirect result of excessive vegetative growth [23].

Since, to the best of the authors’ knowledge, the influence of the SHD training system on almond trees has not been reported in the literature, the aim of the present study has been to fill this knowledge gap. The phenological stages throughout the vegetative cycle have been monitored, comparing two production systems (conventional vs. SHD) during two growing seasons through various productive parameters, and the influence of canopy architecture on light interception has been investigated. The obtained results should be useful for feasibility studies related to the implantation of the SHD system in future plantations in the Mediterranean region.

Material and Methods

Location

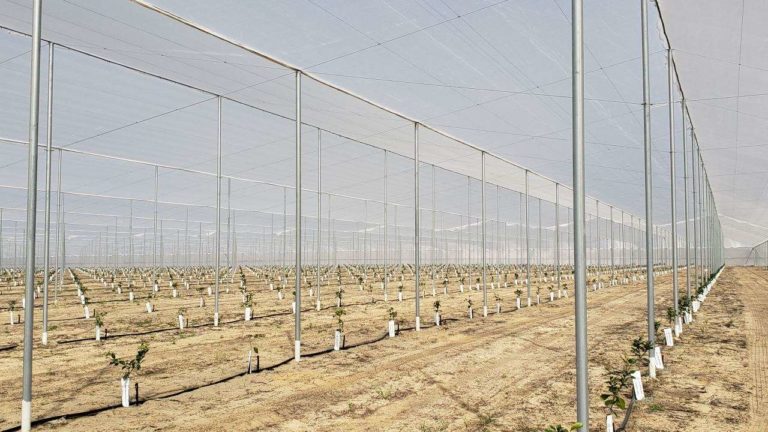

The study was carried out in 2018 and 2019 in an experimental almond tree plantation in the “Mas d’en Félis” farm (Figure S1), in the municipality of La Granja d’Escarp, Lleida, Spain (polygon 5, plot 592; coordinates 41º24’041.7” N 0º22’39.4” E; 78 m above sea level). Almond trees were planted in both systems at the beginning of 2010. For the SHD plantation, the rows were oriented in north-south direction as far as the topography of the plot allowed it.

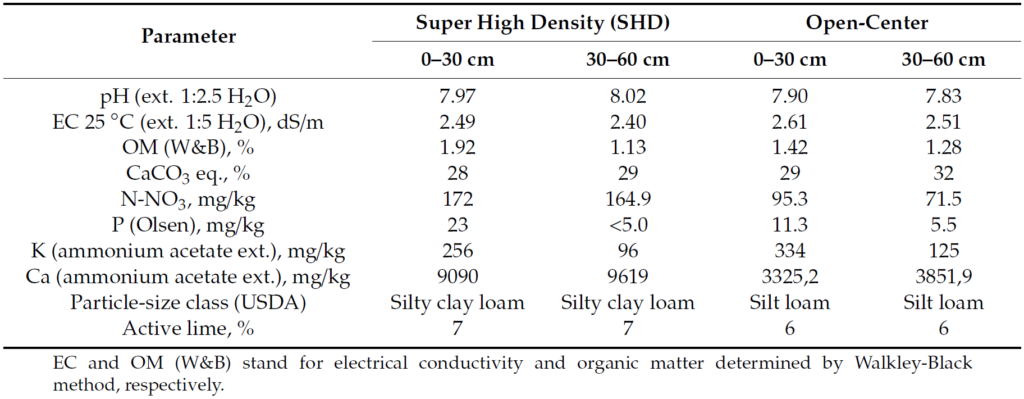

The soil can be classified as Xeric Torriorthent, and basic information from the soils analyses is summarized in Table 1. The physicochemical properties are typical of most of the soils located in the lowlands of Ebro Valley (NE Spain). The most relevant traits were the high pH and CaCO3 eq. As a consequence, it is a common practice to supply iron chelate and others chelated nutrients (e.g., Zn and Agronomy 2019, 9, 874 3 of 15 Mn) through the drip irrigation system, minimizing the effect of differences in the excess soluble Ca in the soil. Differences in N-NO3, tentatively ascribed to fertilization leftovers from previous season, should not have a significant effect on the reported results (e.g., on vigor), given that a drip irrigation system was used to supply the nutrients in both tested systems, which would mask aforementioned differences to a large extent.

Plant Material and Tree Spacing

The two training systems were tested using ‘Soleta’ cultivar (‘Blanquerna’ x ‘Belle d’Aurons’; acronym F-4-10, clone 503, registration number in the OEW 20054616), obtained by CITA (Aragón, Spain). It is an auto-fertile, late flowering, medium-late ripening cultivar, with an interesting quality and production. The interested reader may find further information on this cultivar in [24–27].

Combinations of ‘Soleta’ with two rootstocks with different planting distances and training systems were compared. On the one hand, trees grafted onto Rootpac-20 rootstock (Agromillora Catalana, Spain), with a 4 m x 1 m planting distance (2500 trees/ha), with an anarchic hedgerow formation system but maintaining in general the central leader (2.70 m high, 0.90 m wide and with a height at the cross of 0.5 m). On the other hand, trees grafted onto GFF-677 rootstock (INRA, Montpellier, France), with a 6 m x 6 m planting distance of (278 trees/ha), with an open-center formation system (tree dimensions of ca. 4.85 m high, 4.9 m maximum diameter and height at the cross of 1.3 m).

Cultural Practices

High frequency localized irrigation was used, with applied doses of ca. 6700 m3/ha in the SHD system and ca. 7900 m3/ha in the open-center formation system, given that the rainfall in the area during the growing seasons were lower than 300 mm. Concerning fertilization, the characteristics of the soil were taken into account, and 240 inorganic N units, 60 P2O5 units and 190 K2O units were applied per ha and year through the fertigation system.

Regarding soil management, the plantation rows were kept clean of weeds through the application of herbicides, while the streets remained in non-tillage, and weed removal was done through strimmer passes. Eight phytosanitary treatments were applied with a tractor-mounted atomizer, carried out according to the recommendations of the farm advisor, and in good agreement with the integrated pest management guidance provided by the Agriculture Department of the Generalitat de Cataluña regional government.

Both training and production pruning were carried out mechanically, with a disk machine. Harvesting was also carried out in a mechanized way for the two types of training system, albeit using different equipment: the hedgerows were harvested using an over-the-row machine, while in the open-center trees a shaker with an umbrella was used instead.

Experimental Design

In the case of SHD trees, because of their small volume, five experimental units of three consecutive trees/unit were monitored. On the other hand, in the case of open-center trees, three experimental units of one tree/unit were chosen. The reason behind the choice of these different experimental designs was the effort involved in the flower and fruit counting, discussed below, which were conducted for the entire trees (instead of using a few branches for estimation purposes).

Flower Counting, Fruit Counting and Harvest

In March, the total number of flowers of each of the experimental unit was manually counted during the phenological state D (at the time in which petals are seen), and in July a fruit counting was carried out to determine the fruit set rate, defined as the percentage of flowers that persist until ripening, and which depends on the viability of pollen and on the available carbohydrates, which may vary from one year to another [28]. An advanced date was chosen for this counting to avoid errors resulting from fruits purged by the tree that do not mature (such natural fruit drop early in the season would work as a mechanism that enhances spur survival [29]). In September, the fruits were collected for each of the experimental units of both training systems, and homogeneous samples of 1 kg of almonds with hull were extracted from each of the replicates. Almond in shell weights (after hulling, expressed in g), kernel weights (after shelling, expressed in g), kernel yields (in %) and humidity were determined. The results were also expressed as almond fresh fruit yields, almond in shell yields and kernel yields in kg/tree and in kg/ha. The latter was estimated considering the planting densities indicated in Section 2.2. For the calculation of the yield per canopy volume (in g of kernel/m3), the canopy volume was estimated by approximating the tree shape to an ellipsoid in the case of open-center trees [30] and to a rectangular parallelepiped in the case of SHD trees. Yield effciency (in g of kernel/cm2) was determined by dividing kernel weights per tree by the trunk cross-sectional area (TCSA) measured 20 cm above the scion.

Equipment and Measurements

Fluorescence measurements were performed with a Handy PEA (Plant Effciency Analyzer; Hansatech Instruments, Pentney, Norfolk, UK), on a bimonthly basis since the end of May till the beginning of September. Ten measurements were taken for each block in the case of trees in hedgerow formation, while 17 measurements were taken for each of the open-center almond trees.

Leaf chlorophyll status was also monitored bimonthly throughout the entire vegetative period (May–September). A SPAD-502 m (Minolta, Osaka, Japan) was used. In SHD trees, 20 values were collected for each block, equally distributed between east and west orientations. In the open-center trees, measurements were distributed along the entire perimeter of the tree, obtaining 30 measurements per tree and date.

Photosynthetically active radiation measurements were carried out with an AccuPAR LP-80 linear ceptometer (Decagon Devices, Pullman, WA, USA), on a bimonthly basis, at solar noon. For hedgerow trees, nine measurements were carried out per experimental unit. For the open-center trees, 21 measurements were taken for each individual, distributed in three lines with seven measurements per line (see Figure S2). From the measurements, two indices were determined: the percentage of intercepted radiation (LI) and the LAI (leaf area index) [31]. In addition, to gain insight on the presence of shaded canopy regions (in which light levels may be below threshold values for the sequential steps of shoot growth, floral initiation, flowering, fruit formation and fruit filling [32]), tempo-spatial photosynthetically active radiation (PAR) measurements were also conducted in both systems at different times (every 60 or 90 min, from 08:00 until 18:00/18:30, depending on the training system) on three dates (at the end of June, July and August) in the 2019 growing season. A scheme of how measurements were conducted is presented in Figure S3.

Statistical Analyses

Prior to the analyses, the assumptions of independence, normality and homoscedasticity were checked. for all groups. Since the data did not met the normality requirement, checked with a Shapiro–Wilk test, and the homoscedasticity requirement, checked with a Bartlett’s test, Kruskal–Wallis non-parametric test was used. Conover-Iman test was chosen for post hoc multiple pairwise comparisons of the agronomical characteristics and fruit quality parameters. Productive parameters data was also subjected to principal component analysis (PCA) with the Varimax rotation method with Kaiser normalization. In the PCA, the components that accounted for most of the variance were selected, and those that contained only a small percentage of the variance of the original data were removed.