Mechanization of Pruning, Flower/Fruit Thinning, and Harvesting in 2D Peach Orchards

In most fruit crops, labor represents the main production cost, ranging from 45% to 75% for stone fruits such as peaches and cherries, respectively

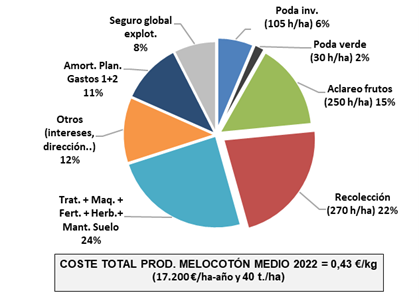

Figure 1 shows the cost breakdown for a mid-season peach variety in the Ebro Valley. It can be observed that harvesting, thinning, and pruning are the most significant cost components.

The increase in labor costs over the past decade has nearly doubled compared to the price received by producers. Moreover, labor availability and skill levels are steadily decreasing (Minas et al., 2023; Iglesias et al., 2023). In this scenario, there is no alternative but to use labor more efficiently, simplify tasks, and substitute part of these with machines for operations like flower and fruit thinning, pruning, and harvesting. The following sections present various aspects related to pruning, thinning, and harvesting in peaches.

PRUNING

Dormant Pruning (Winter Pruning)

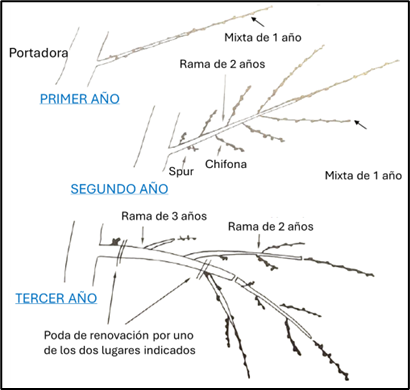

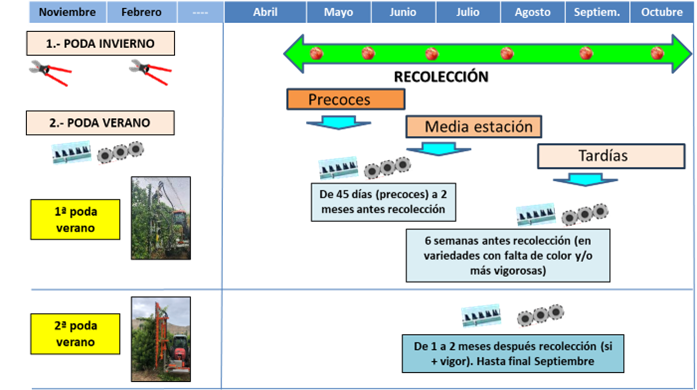

This is the most common for all types of orchards and is typically assisted by electric or pneumatic shears, sometimes with individual or collective platforms to reach the tops of trees in non-walkable orchards (Photos 1 and 2). Figure 2 shows the fruit-bearing organs and pruning types used to maintain growth near the main branches. Dormant pruning can be mechanized with disc pruners when the goal is to reduce canopy volume, though doing so in dormancy may stimulate tree vigor.

Figure 2. Development and training of mixed shoots during the second and third years, indicating whether to retain or prune (left) (Iglesias et al., 2023). Successive dormant prunings in flat systems to keep growth near the main branches (right) (Brunner, 1990).

Photos 1 & 2. Two options for pneumatic-assisted winter pruning. Vase-shaped on the left, flat triple-axis on the right.

Green or Summer Pruning

Photos 3 & 4. Two options for mechanized green pruning in 2D orchards: topping in two adjacent rows (left) and V-shaped window in a vase form using the new Jumar model.

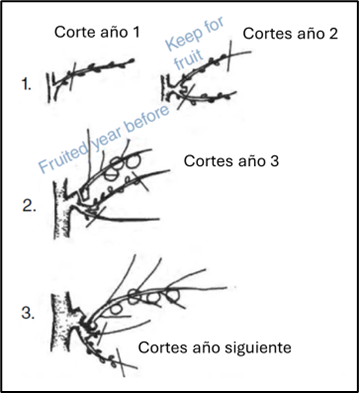

In mature axial systems (single, double, or triple axis), green pruning is usually mechanized and done before or after harvest, depending on harvest timing (Photos 3 & 4). In some varieties and regions, two passes are done as shown in Figure 3. With low to medium vigor rootstocks, typically only one green pruning pass is performed after harvest. Another option is pre-winter green pruning, done before leaf fall, typically in September. This is usually manual in vase shapes and mechanical with cutter bars in flat forms. In both cases, it enhances light exposure to fruiting wood (mixed shoots, bouquet spurs) for the following season and improves floral bud quality. In flat forms, it also defines final canopy volume and reduces winter pruning time by ~30%. This can be done in one or two rows, combining lateral cuts and topping depending on the machine. Three types of machines are used:

- Rotary or helical blades (faster),

- Reciprocating blades (cleaner cuts on tender shoots, slower),

- Toothed discs (used post-harvest or for thick branches and vase training).

Some pruners combine lateral reciprocating blades and topping discs.

Figure 3. Options for summer or green pruning in peach depending on harvest timing.

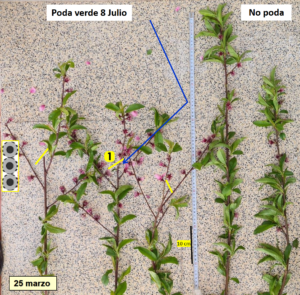

Green pruning limits canopy expansion between rows and in height, improves light penetration, and controls tree vigor. Cutting the distal ends of mixed shoots (Photo 5) promotes new mixed shoot development near the base, which will bear the next year’s crop (Photo 6). As a pre-pruning, this simplifies winter pruning by allowing easy selection of new fruiting shoots (Photo 6).

Cutting near the axis (~5 cm long) with a flat cut encourages new mixed shoot development.

Photos 5 & 6. Detail of green mechanical pruning (yellow) done late May with reciprocating blade (photo taken in July, left). Result of green pruning (blue) and after winter pruning (yellow), photo from late February.

Thinning

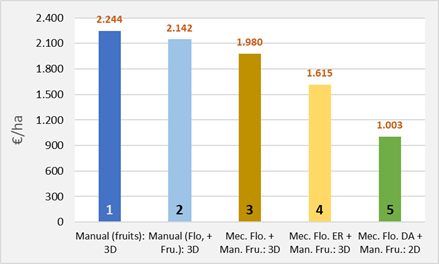

Figure 4. Annual cost (€/ha) for different flower and fruit thinning methods in peach for vase (3D) and central leader (2D). From left to right: 1. Manual fruit thinning, 2. Manual flower + manual fruit thinning, 3. Mechanical flower + manual fruit thinning, 4. Mechanical flower with Ericius + manual fruit thinning, 5. Mechanical flower with Darwin + manual fruit thinning.

Photos 9 & 10. Mechanical flower thinning in peach using Ericius in vase and Darwin in central leader systems.

Harvesting

Photos 11 & 12. Vase harvesting with GF-677 rootstock using sled ladders for upper canopy (left). Fully walkable harvesting in central leader system with Rootpac-20 rootstock (right).