Autonomous Orchard Sprayers: The Next Revolution in Agriculture Equipment

GUSS Automation’s autonomous sprayers incorporate the most advanced technology to change the direction of the agricultural sector and its companies. With the GUSS (Global Unmanned Spray System) company, producers are able to increase their efficiency and precision as well as keep their workers in the best working conditions ever seen before. This article describes the main characteristics of the autonomous sprayers developed by GUSS over the last decade, combining the latest technological advances in geolocation (GPS), LiDAR technology, sprayers and artificial vision for their positioning, guidance and efficient application of sprayers. phytosanitary treatments.

The GUSS proposal in treatment equipment: characteristics and models

Like many revolutionary inventions, GUSS was developed out of necessity. As Dave Crinklaw dealt with the obstacles of high costs of materials and labor in his orchard spraying business, he found himself looking for answers and the solution came in the form of a driverless orchard sprayer.

After years of research and development, GUSS was born. Crinklaw began using GUSS in his spraying business and when local growers caught wind of his development, they wanted GUSS in their orchards as well. In 2019, GUSS Automation sold their first autonomous orchard sprayer and the word spread quickly about this cutting-edge technology.

GUSS uses a combination of GPS, LiDAR and the latest technology to autonomously roll through the orchard spraying each tree with precision and efficiency. At 24-feet long, 6-feet-4-inches tall and 7-feet-6-inches wide, GUSS is designed to drive comfortably through the orchard. GUSS includes the 600-gallon tank, 32 nozzle spray manifold with individual shutoffs, up to a 14 hour run time with the 90-gallon fuel cell, and 3.8-liter Cummins diesel engine to keep GUSS moving row after row, field after field, day or night.

A single employee can monitor and operate up to eight GUSS machines from the vehicle while the nurse trucks supply the spray product when GUSS signals for a refill. GUSS draws on rich data files to show what was sprayed, where it was applied and when it was applied to fine-tune the operation.

Mike Carr of Five Star Farms has found great success with GUSS. “GUSS has had a major impact on my farm by allowing me to do more with less. We get more acres done every shift due to less stopped and downtime. My dependency on labor and all the challenges that come along with it has greatly decreased. In my opinion, GUSS autonomous sprayers are the only way to go moving forward.”

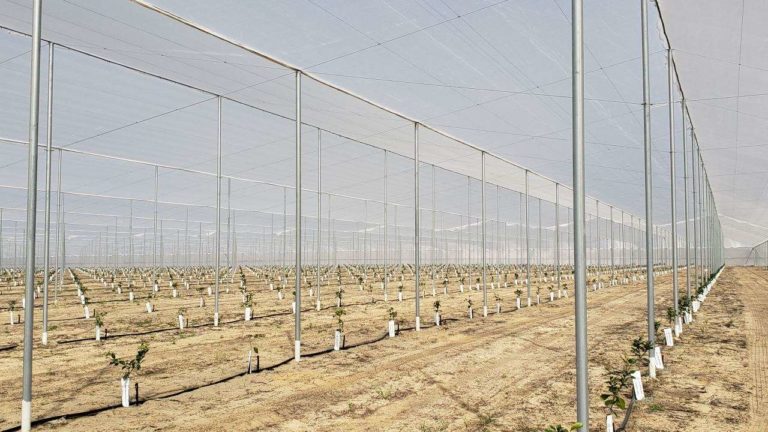

As the word spread about the successes farmers were having with Orchard GUSS, the excitement grew. GUSS customers throughout the world were asking for a smaller GUSS specifically designed for vineyards and high-density orchards. GUSS Automation jumped into action to design and develop mini GUSS.

Mini GUSS may be smaller than its predecessor Orchard GUSS, but it is MIGHTY! The standard mini GUSS is 6-feet wide, 5 ½-feet tall and 20-feet long with 28 ceramic nozzles. It has a 400-gallon tank and a 3.8-liter Cummins diesel engine to tackle the most strenuous terrain. Mini GUSS can run up to 12 hours with the 77-gallon fuel cell.

GUSS Automation offers two tower options for mini GUSS. The vineyard tower is 9-feet tall with 22 ceramic nozzles and the apple tower for high-density orchards is 9-feet-2-inches tall with 44 ceramic nozzles. With the smaller size of mini GUSS, it can easily roll down 9-foot rows spraying with precision and efficiency. Mini GUSS will be making its debut in spring of 2022.

As technology progresses and makes its way through the agriculture industry, GUSS Automation continues to make safety their priority by implementing advancements in the autonomous vehicle market. The Defender™ vest was developed by GUSS Automation to add an additional layer of employee safety to the obstacle detection sensors already on GUSS.

GUSS autonomously sprays orchards with increased efficiency and precision as well as keeps crews safer than with traditional orchard spraying equipment. Not only does GUSS minimize exposure to the materials being sprayed by removing individuals from the orchard, GUSS also includes many other safety features.

GUSS Defender™ vest is patent pending technology and utilizes a small wireless transmitter that automatically pauses the autonomous machine when the person wearing the Defender™ vest is detected. GUSS will not resume operation until the individual is clear of the area surrounding the vehicle creating a safer environment for the crew members.

“Developing sound safety systems is our duty as a leading pioneer in the autonomous farm equipment sector,” stated Gary Thompson, COO of GUSS Automation. “The Defender™ vest was the next logical step for us in our quest to maximize the level of safety around GUSS machines, adding an additional layer of redundant safety to an already robust safety stack.”

This proprietary technology of the Defender™ vest is not solely for autonomous agriculture equipment, but could potentially be added to any vehicle to improve safety. The batteries located in the transmitter of the high visibility safety vest have an estimated 1.5-year life. No daily charging is necessary, making it easy and convenient for employees to use.

After strategic infield testing, the first GUSS machines utilizing the Defender™ vest technology rolled out to customers in April 2021. Defender™ technology is now standard on every GUSS vehicle to maximize safety for farmers, growers and their crews. Being on the forefront of autonomous agriculture equipment, GUSS Automation makes safety their highest priority and will continue to innovate in this field.

GUSS machines are also available with Select Spray. Select Spray allows for increased precision and accuracy by targeting the specific tree no matter the size and spraying the determined amount of material needed.

This spraying technique also minimizes labor, time, drift and material costs. With Select Spray technology, spraying crops has never been more accurate.

“We absolutely love the machines. We do at least 40-50 acres more per day with a crew of four versus the traditional manpower-driven tractor. The best things are efficiency, safety and precision.” said Ryan Boucher, co-owner of Blair Ground Services. “A lot of things made us opt for the machines, like efficiency. And labor costs are going sky high, so that was a big factor. There’s less liability and more dependability.”

GUSS Automation has hit their stride. In just a year and a half, they have delivered their 100th autonomous orchard sprayer and now have GUSS machines spraying throughout the United States and in Australia and looking to expand into the European market in the near future.

The growth of GUSS has been an exciting journey for the GUSS team. GUSS Automation, LLC currently has 35 employees which includes a tech team, engineers, field testers, customer success team, and their fabrication and assembly crews. With the rising demand for GUSS, they are streamlining the manufacturing process to double production to two GUSS machines per week. GUSS Automation has also built their outside team of trusted authorized GUSS dealers in the US and Australia to meet customer needs.

GUSS Automation continues to be an industry innovator with plans for additional autonomous agriculture equipment. With the ever-increasing cost of spray products and labor, autonomous spraying is an impressive tool for increasing productivity and improving the overall operation for farmers and growers worldwide.

Click here to see GUSS in action.