See Citrus Mechanical Harvesting in Action

Learn how new grove architecture could change the way you grow citrus

If you ask growers what their top two challenges are, most will list citrus greening (also known as HLB) and sourcing affordable and reliable labor. On February 8th, a grove demonstration will be hosted that might help growers in both areas.

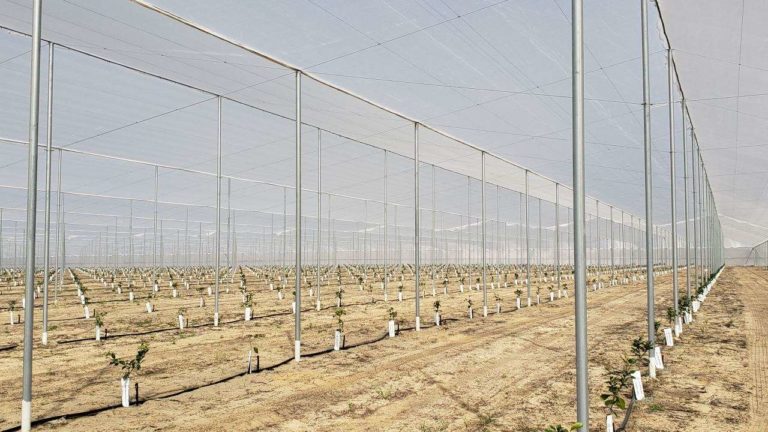

The field day will be held at Lost Lake Groves just outside of Lake Placid, Florida where A 14-acre block is using the Pedestrian Hedge Model. This model allows for mechanical harvest, which helps address the labor issue. And the trees seem to be withstanding the effects of HLB better than conventional plantings with larger trees.

The field demonstration will feature mechanical harvest utilizing an Oxbo 6430. There will also be a handpicking demonstration to show how the smaller tree size lends itself to easier hand harvest. In addition, attendees will be able to evaluate HLB effects in the grove.

“In earlier tests, we have seen that the machine does an excellent job harvesting the fruit with little to no damage to the fruit or trees,” says Clay Pederson, Managing Director of Agromillora Florida.

“Although all the trees are assumed to have greening, the smaller-sized trees seem to be faring much better than larger, conventional trees. This effect has already been confirmed by Brazilian researchers from Embrapa and Fundecitrus in their recent investigations.”

“These results look promising and could help citrus growers deal with two of their biggest challenges”.

We are excited to demonstrate this during the field day in February. We’ll also be explaining how the Agromillora Smart-Tree® can help citrus trees get off to a strong start in a high-density setting. The SmartTree format provides multiple advantages from the use of a micropropagated clonal rootstock, a smaller format that facilitates handling and planting, an included sprout and herbicide protector, as well as a biodegradable paper pot that is easy to plant and produces healthier roots with no circling.”

Agromillora has been collaborating with the Lost Lake grove owners to introduce the Pedestrian Hedge Model to Florida Growers. The company has experience with high-density planting in citrus and in other crops around the world and is applying it to Florida citrus production.

The grove was planted in May 2018 and has experienced impressive growth. Just over a year after planting, the trees were already 4-feet tall and had developed an extensive root system. Today, the trees range from 7-feet to 8-feet tall with a 3-foot width. They are expected to top out at 10 feet. This season will mark the first commercial harvest of the grove.

Training for Success

With high-density and trees planted on a 12-foot by 4-foot spacing, rows can be trained for mechanical harvest and more efficient hand harvest. That’s been the practice in the Lost Lake citrus grove. The Pedestrian Hedge Model can range in spacing and density from 500-908 trees per acre where the size and shape of the hedge is key.

In addition to harvest efficiency, the system also provides benefits in more efficient use of inputs and irrigation. In the Lost Lake grove, microjets are situated one for every two trees since spacing is so close.

“One of the things that helped Agromillora get established as a company was propagating super-high-density olives in Europe nearly 30 years ago. We have talked about high density or mechanical harvesting around the world, and here in Florida, for years,” Pederson says.

“But what we are doing at Lost Lake is a different way of approaching mechanical harvest. This is not the old tree-shaker model where we tried to harvest existing trees with newly engineered machines. Here we are growing and grooming the trees, from the beginning, to be mechanically harvested with existing equipment.