2D planting systems A novelty in almond trees, a reality in fruit trees.

Towards high efficiency (Part II)

2D planting systems and the importance of low-vigor rootstocks

As just explained, the species in which plantation intensification has been faster are those in which dwarfing rootstocks were available, such as apple and pear. In stone fruit species, this innovation has come more recently because the process of selecting lower-vigor rootstocks has been slower and is still ongoing It is true that in these species, high-density plantations have been carried out thanks to the use of paclobutrazol, registered in Spain for use as a growth regulator in stone fruit species, effective and at low cost. However, for sustainable long-term production systems, it is evident that 2D planting systems are required, with minimal use of plant growth regulators, also because their availability in the future is more than uncertain. Therefore, in the design of future plantations, this point must be very present, and vigor control must integrate different techniques such as the most suitable rootstock according to the type of soil, deficit irrigation, green pruning, or root pruning, among other techniques.

The transition

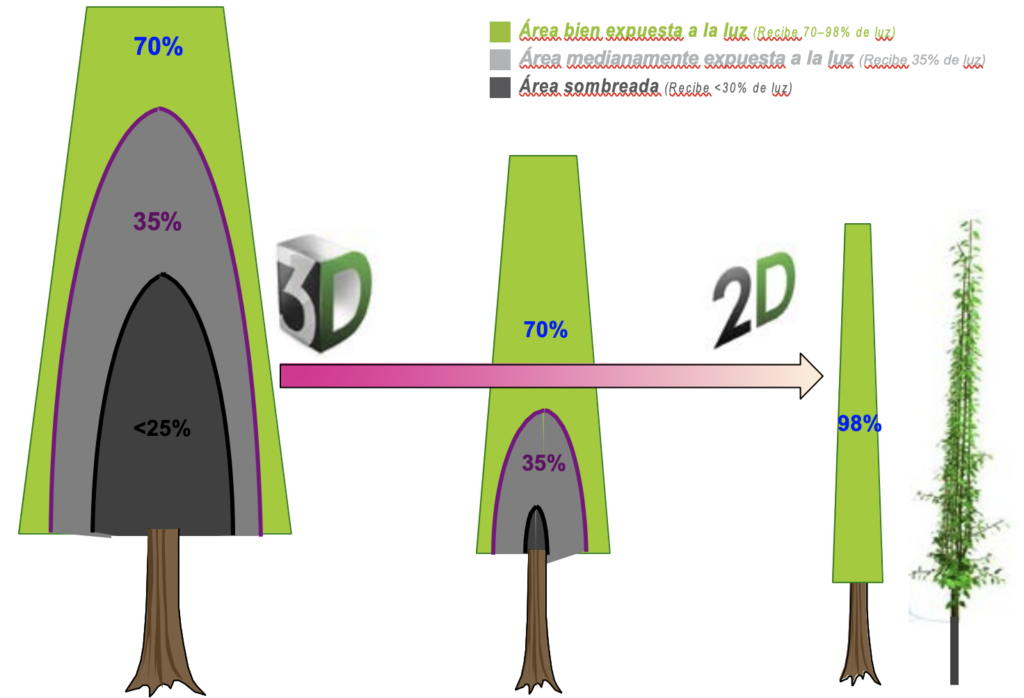

The continuous transition to trees with smaller canopy volume, in addition to enabling faster entry into production, has very important implications in their management due to easier access to the canopy to carry out different cultivation operations manually such as pruning, fruit thinning, or harvesting. In addition, in the last two decades, such accessibility has become increasingly important for machines that perform these operations either entirely or partially, reducing costs. The robotization of many tasks traditionally performed by hand is an irreversible trend in all economic sectors, and the horticultural sector is undoubtedly not going to be the exception. Another aspect to highlight in smaller canopy volumes is better illumination, resulting in better and more uniform coloration in red varieties and, in general, better quality and uniformity of fruits. Figure 3 illustrates how reducing the canopy volume, associated with an axial shape, positively affects light distribution and illumination, reducing shaded areas, with the consequent positive effect on fruit quality and, indirectly but no less importantly, accessibility for people and machines.

Why Smaller Trees?

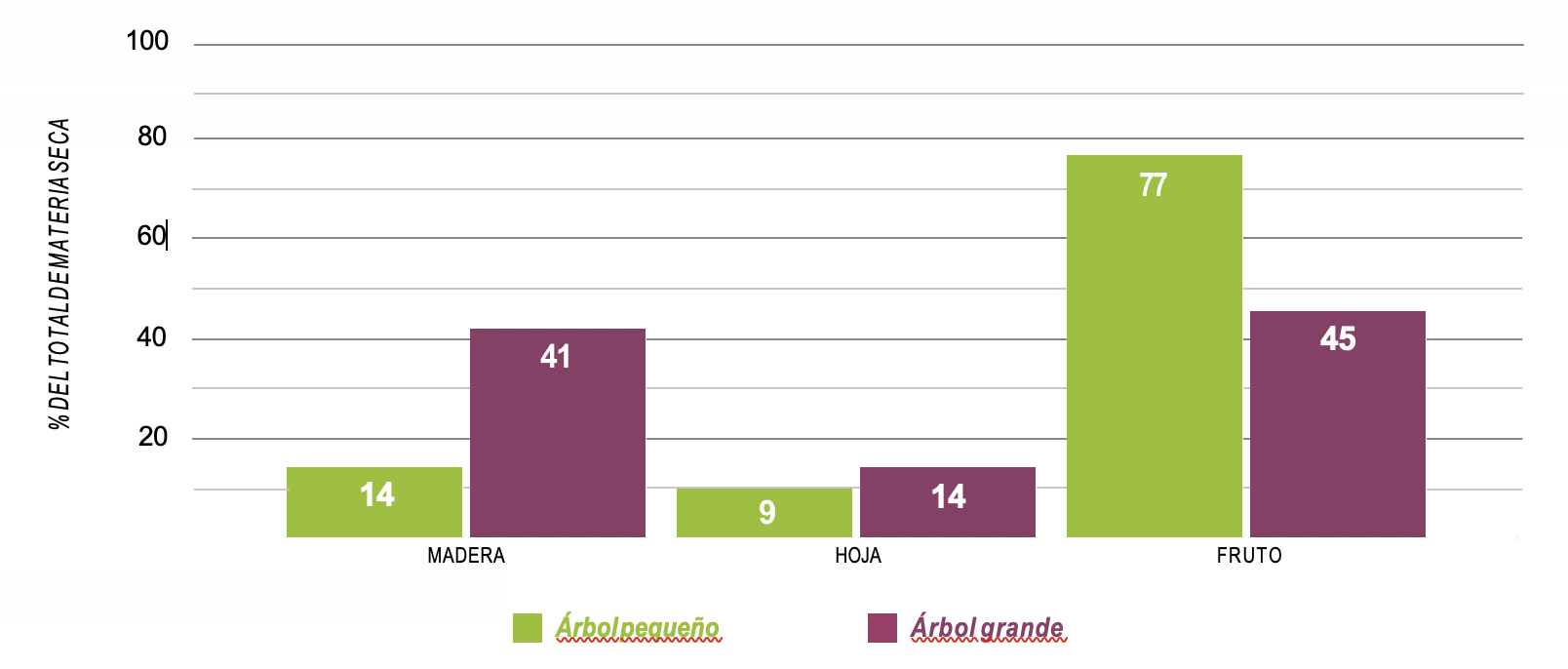

There are numerous references that demonstrate that in fruit species (apple, pear, peach, cherry, etc.), smaller trees are more efficient. “Enjoy the little things, for one day you may look back and realize they were the big things,” said tenor R. Briault. In the last two decades, the trend towards using smaller trees has also become widespread in olive cultivation, with super-intensive plantations, and more recently, a similar process is occurring in almond cultivation. The distribution/partitioning of carbohydrates from photosynthesis and consequently, dry matter, towards the fruit, leaves, or wood, is affected by the size of the tree, as shown in Figure 4. It is clear that smaller trees are more efficient in distributing carbohydrates towards the fruit, at the expense of the trunk and leaves. This implies greater productive efficiency in terms of the number of fruits/m3 of canopy or production/cm2 of trunk section, with the consequent benefit for the producer. This improvement in efficiency through the use of smaller volume trees with dwarfing rootstocks such as M-9, is evident, for example, in apples in the province of Südtirol (Italy), where average production increased from 28.3 t/ha in the period 1970-1978 to 54.6 t/ha in the period 2009-2017, tripling production.

The greater efficiency of smaller trees is due to several factors such as:

- Lower percentage of structural wood, resulting in a more efficient distribution of carbohydrates and consequently, dry matter. That is, a higher percentage towards the fruits, rather than towards the wood or leaves (Figure 4)..

- Smaller canopy volume, resulting in greater efficiency by significantly reducing shaded areas (Figure 3). Consequently, the fruits and leaves are exposed to similar illumination, resulting in more uniform fruit quality.

- Fruit-bearing organs and fruits closer to the trunk, so that the transport and distribution of water, nutrients, and assimilates require less energy expenditure and therefore are more efficient.

- Greater accessibility of the canopy both for manual tasks (pruning, thinning, harvesting) and for tasks performed by machines (pruning, flower and fruit thinning, harvesting platforms). Accessibility has been significantly improved in the last two decades through the adoption of flat or 2D training systems (fruit walls), which also leave the door open for harvesting in sweet fruit.

- Most or even all of the cultivation tasks can be carried out from the ground, without the need for ladders, improving labor efficiency and requiring less physical effort, enhancing worker comfort.

- Greater accessibility of the canopy to manual tasks reduces their cost, risk, and enhances their efficiency. Furthermore, the possibility of carrying out some operations in a mechanized manner significantly reduces production costs.

- Improved productivity in mature plantations and faster entry into production, simply by increasing planting density and allowing the tree to quickly occupy the allocated space. As a trade-off, planting costs increase due to higher planting density and the need, in many cases, for support structures.

CONCLUSIONS

Based on the above, it can be concluded that the progressive adoption of intensive plantation systems in different fruit species is associated with greater efficiency of the plantations, because the rootstocks on which they are based are also more productive. In addition, these systems allow for faster entry into production, better canopy illumination, and the adoption of more accessible flat forms for both manual work and machinery, improving efficiency. All of this, coupled with the also improved efficiency of phytosanitary treatments enables more precise and efficient fruit growing. Intensive plantations should be based on the development of bidimensional canopy forms that are easy to form, since available labor is becoming less specialized, and they are also susceptible to partial or total mechanization, depending on the species. However, these intensive 2D plantation systems require considerably higher investment and proper capitalization. This investment will be recovered in a shorter period depending on the profitability of the crop. Therefore, they are more interesting for crops with promising price prospects and when dealing with large areas and limited labor availability. Finally, it must be remembered that these are efficient systems, provided that the production technology is adequate. Any mistake in the choice of plant material, plantation design, pruning, irrigation, fertilization, treatments, or load regulation, among others, can thwart a significant investment and the efficiency of the system.

If you liked this post, we suggest reading the following:https://www.agromillora.com/nuevas-variedades-para-el-olivar-en-seto/

If you liked this post, we suggest reading the following:https://www.agromillora.com/nuevas-variedades-para-el-olivar-en-seto/